Barcodes are ubiquitous symbols that encode information about products, packages, and processes. They are used for identification, tracking, inventory management, quality control, and more. However, not all barcodes are created equal. Some barcodes may be damaged, distorted, faded, or poorly printed, making them unreadable by scanners or humans. This can lead to errors, delays, rejections, and losses for businesses and customers.

To prevent these problems, barcode inspection is a crucial step in ensuring that barcodes meet a consistent level of quality and readability. Barcode inspection involves checking the physical characteristics of barcodes against predefined standards and specifications. These include parameters such as size, contrast, alignment, quiet zone (the blank space around the barcode), modulation (the variation in reflectance between bars and spaces), print quality (the presence of defects such as spots or voids), decode (the ability to extract data from the barcode), and symbology (the type of barcode).

Photo Credit: Advanced Illumination

Barcode inspection can be done manually by human operators or automatically by machine vision systems. Machine vision systems are devices that use cameras and software to capture and analyze images of objects. Machine vision systems can perform various tasks such as measurement, identification, verification, classification, sorting, counting, etc. Such machine generated inspection is beneficial for:

- Speed: Machine vision systems can inspect barcodes at high speeds and frequencies without fatigue or distraction. For example, a study by ⁴ found that machine vision systems could identify fast-moving parcels with barcodes at rates up to 6000 parcels per hour.

- Accuracy: Machine vision systems can detect subtle defects or variations in barcodes that may be missed by human eyes or scanners. For example, a study by ¹ found that machine vision verification could identify bad codes before they result in costly failures.

- Consistency: Machine vision systems can apply consistent criteria and standards for barcode inspection across different batches, locations,and times.For example,a study by found that machine vision systems could reduce human errors,and variability in barcode verification.

- Traceability: Machine vision systems can store,and transmit data about barcode inspection results for quality control,and compliance purposes.For example,a study by found that machine vision systems could provide real-time feedback,and reports on barcode quality.

How Does Machine Vision for Barcode Inspection Work?

Machine vision for barcode inspection typically involves four main steps:

1) Image acquisition: This is the process of capturing an image of the barcode using a camera or a scanner. The image quality depends on factors such as lighting, resolution, focus, angle, and distance.

2) Image processing: This is the process of enhancing and preparing the image for analysis using software tools and algorithms. This may include operations such as filtering, thresholding, binarization, segmentation, and morphology.

3) Image analysis: This is the process of extracting information from the image using software tools and algorithms. This may include operations such as decoding, verification, grading, and validation.

4) Image output: This is the process of displaying or transmitting the image analysis results using software tools or devices.This may include operations such as visualization,database storage,network communication,and feedback generation.

Machine Vision for Barcode Inspection Applications

Machine vision for barcode inspection has many applications in various industries,such as manufacturing where Machine vision can help manufacturers ensure that their products have readable and compliant barcodes before they leave the factory. Additionally helpful in logistics where machine vision can help logistics providers sort,direct,and deliver parcels with barcodes more efficiently and accurately. Meanwhile, in retail machine vision can help retailers scan,and manage inventory with barcodes more effectively.This can optimize stock levels, replenishment, and pricing.

What Products Help With Barcode Inspection?

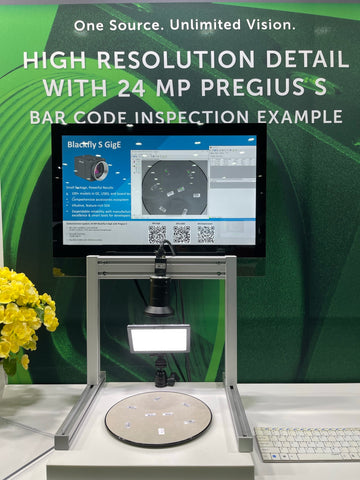

A high speed industrial camera is key for efficient bar code reading,Teledyne FLIR's Blackfly S series cameras are a popular solution for bar code inspection. As the example photo below demonstrates, the system setup includes the camera, lighting, the objects of focus, software, and a viewing device.

Photo Credit: Lore+ Technology

JAI Solutions

Another ideal camera for barcode inspection would include JAI's Apex or Sweep series. JAI offers the advanced UV camera option, which allows for the reading of lot numbers and barcodes even when they're invisible to the human eye. The cameras are also backed by a six year warranty.

Other helpful components of this system would also include filters such as MidWest Optical filters or Schneider Optic filters, as well as an excellent lighting solution such as Advanced Illumination lighting or Smart Vision Lighting.

Would you like to add to upgrade your barcode reading application? Contact us for assistance, pricing, and technical support!

Editor's Note: We would like to thank the helpful Bing AI, who helped to contribute to some of the information listed in this blog post.